professional factory for Maize Corn Grinding Machine - 120/24h Wheat Flour Milling Machine – Hongdefa Detail:

Products variety

Confectionary Flour: Use up for Cake & Cookie - Macaroni- meaty Supply - Confectionary –Biscuit

Star Flour Grade 1: Use up for high quality bread.

Star Flour Grade 2: Used for baking pastries.

Normal Flour: Use up for baking local breads.

Bran: Use up for bestial food.

Features of Wheat flour millig machine:

1. Turnkey project.

2. Advanced technology support and customized design.

3. Thorough crafts and rational allocation.

4. Low power consumption.

5. Perfect after-sales service.

6. Two year guarantee.

Introduction

1. Input wheat –wheat cleaner– wheat moisture dampener–roller mill–plansifter–good quality flour –packing.

2. The control system: Control panel control or PLC control.

3. Pipe in milling section is stainless steel.

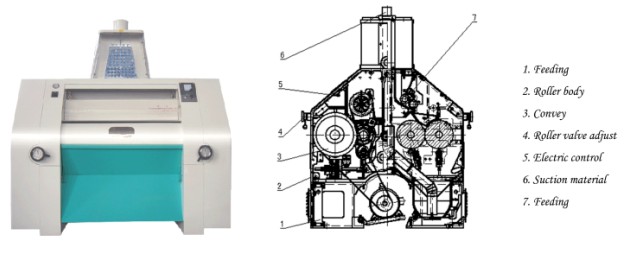

4. Auto-roller mill and plansifter.

5. European Condition dampener.

Introduction of each function of milling machine

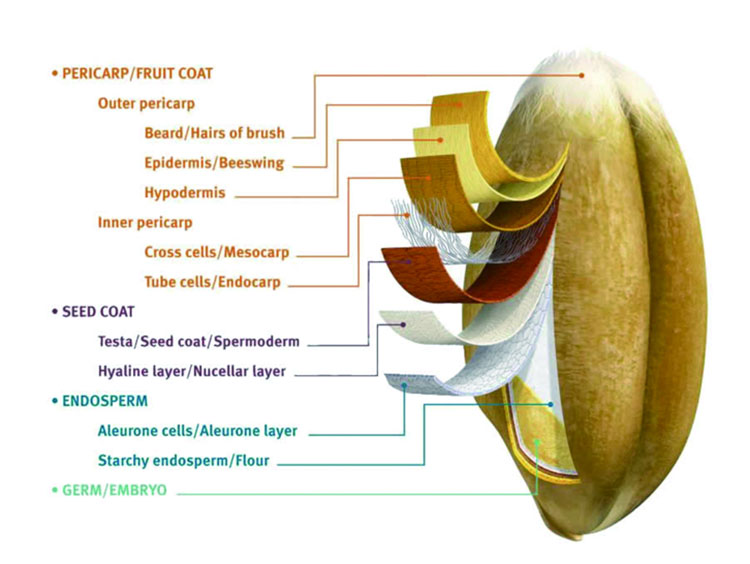

After finishing cleaning, wheat falling into milling machine. At first, extract much of scratch, particles and dunst with good quality from wheat, graded them according to particles’s size and quality then flowing into purifier. At the same time, the scratch system separate hull and endosperm. That can get pure particles and dunst, then make into top grade flour by reduction system. For the sencond grade particles and endosperm will mill by the relevant reduction system to get bran flour. The milling flow can divided into different system, that is Break system, Scratch system,Purifier system, Reduction system, Air transportation system, and packing system.The introduction as below:

1. Break system: The function of the first break system is to break off the wheat and without break the bran. That scrape the big size endosperms away from the wheat, and the rear break system to scrape all the endosperms from bran.

2. Scratch system: The function of scratch system is to separated the bran and endosperm from the reduction system. After this will get good quality endosperm through sifter. The scratch system processing the small size of the material which are not suitable for next break and also not suitble for reduction system, because of the endosperm not pure.

3. Purifier system: Purifier function is picking the scratch, particles, and hard dunst which from break system and scratch system to get bran, endosperm with some bran, and pure endosperm according to the quality. That can let only the pure endosperm falling into the reduction system to avoid the bran spoiled the flour, to increase the flour quality.

4. Reduction system: The reduction system is to grinding the endosperm which from break system and purifier, as the same tiem to grinding the wheat husks and embryo at least. The reduction system adpot smooth roller, can press bran and embryo to flake as the same time grinding the endosperm into the fine powder. Because of the different size among wheat husks, endosperm and embryo, through the impacting detacter, the endosperm will be grinding properly, and the wheat husks and embryo will be make flake. After sifting, it can separate flour from ban and embryo.

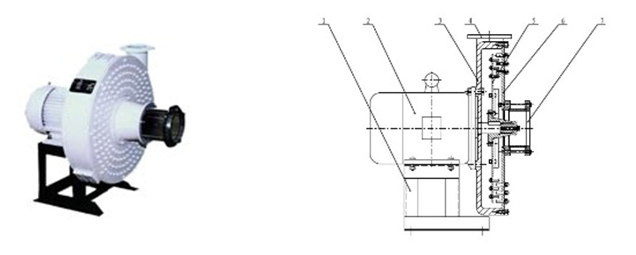

5. Air transportation system: Air transportation system is a tie for grinding, sifting and other assistant machine. Air transportation system can supply power by high pressure blower, through the material pipes and special equipment the grinding material will be send to the sifter to sift and classificating to get flour.

6. Packing system: The packing system function is weigh, sewing.

Packing system: Wheat flour packaging machine can packing with different kind of bags, like 1kgs/2kgs/5kgs/10kgs/25kgs/50kgs.

The function of main milling machine

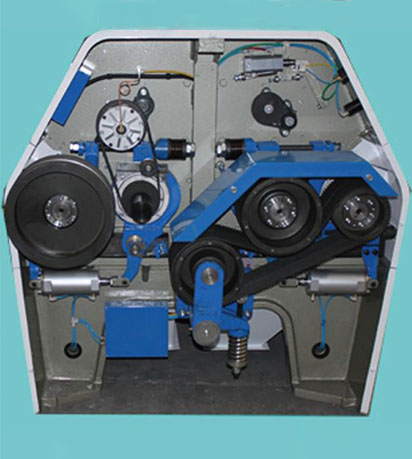

Mill: The mill the most important one machine of whole processing line, is mainly for grinding. To break wheat and bran’s structure, and spearate the wheat husk and the embryo from endosperm by grinding.

Impacting detacher: Big size kernels and dunst from break system, when it is grinding, pressed, will become a quantity pieces and pre-grinding endosperm. It can easy to grinding to flour after the impacting detacher. There are two kinds of impacting machine, mightly one, and common one. The mightly one is used in front reduction system, and common one is used in back reduction system.

1. frame; 2. motor; 3. out cover; 4. output; 5. discal rotor; 6. stator; 7. feeding.

Carbon steel studs with surface nitriding, carburizing treatment, to ensure a good wear resistance.

Advanced processing methods and reasonable manufacturing process to ensure the precision and quality equipment.

The rotor pass a high-precision calibration balancing, smooth and reliable operation.

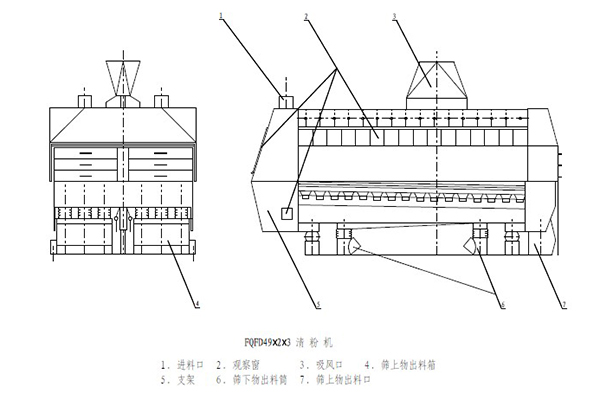

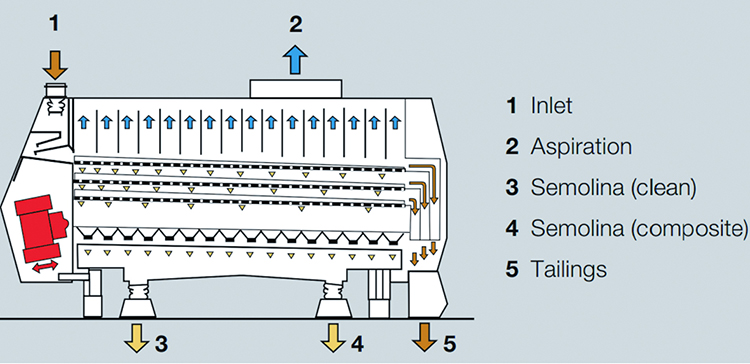

Purifier: It can get the pure endosperm by sifting which is depending on self-vibration and lower pressure blower’s wind power.

1. Feeding; 2.inspection; 3.Absorb wind; 4.up-material box; 5.support; 6.down material output; 7.up-material output.

Heart of the Milling system.

Air duct automatic cleaning system.

Unique feeding adjust system,precent block and material going uniform.

Plansifter: can classify the material that from break, reduction and scratch systems and sifting the flour.

Material: High-strength alloy steel.

Up and down sifter circles with steel plate overall by bending.

Transmission system using spring force component institutions.

Sieve frames of wood coated with synthetic resin,shape no change.

All the inside walls as well as the doors are provided with high-grade insulation.

Vertical and horizontal clamping system.

Package and delivery:

All machines are suitable for sea shipping.

Product detail pictures:

Related Product Guide:

Why Hongdefa maize mill is so popular?

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for professional factory for Maize Corn Grinding Machine - 120/24h Wheat Flour Milling Machine – Hongdefa, The product will supply to all over the world, such as: Latvia, venezuela, Norway, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.