OEM manufacturer Modern Wheat Mill Plant - 500 T/ 24H MAIZE FLOUR MILL – Hongdefa Detail:

Technology guarantee:

a)Guarantee for maize cleaning

The impurity content of the dust should not over 0.3%

The sand stone content should not over 0.02%

b) Waste

After sieving,in each kilogram of crushed stones, the plump corn is not over 100 grains.

After careful sieving, in the wasting things, the good corn is not over 0.01%

After careless sieving, in the wasting things, the good corn is not over 0.01%

In the tailings, the plump corn shouldn't over 0.01%

The form of the package:

Woven bag :50 kg/ bag ( bran, embryo and so on)

Weave bag:25 kg/ bag ( finished product)

Small package:10 kg/bag, 5 kg/bag, 2.5 kg/bag( finished product).

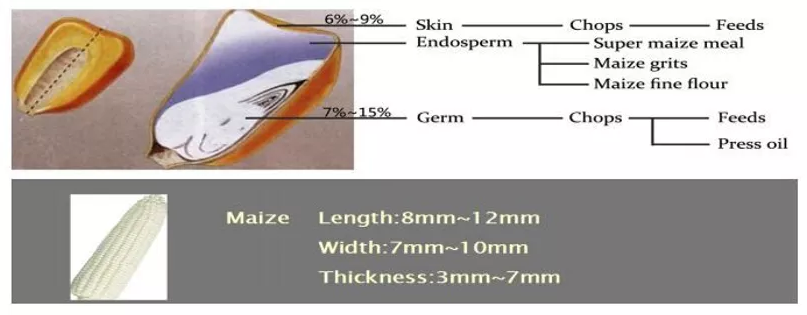

THE MILLING PROCESS

The process of manufacturing the products involves three fundamental sub-processes. The first of these, physically detaches the three components of the maize kernel from each other. with as little dilution or mixing as possible.second, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product

Required The aim of the process then, is to detach the bran and germ from the maize

kernels with a minimum disintegration of either the endosperm or the bran/germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of camp to the very Fine maize flour. Some of the bran and germ are also ground down in the process and a certain amount combined with the ground endosperm to meet the specifications of the coarser meals such as sifted and unsifted maize meal.

Product detail pictures:

Related Product Guide:

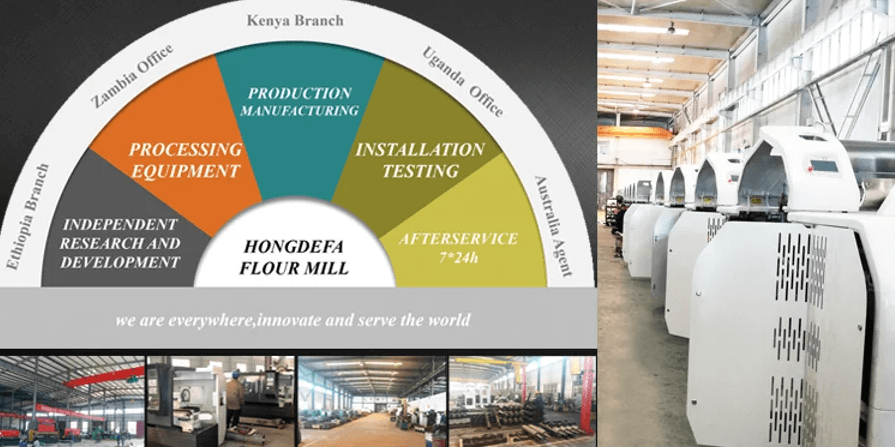

Why Hongdefa maize mill is so popular?

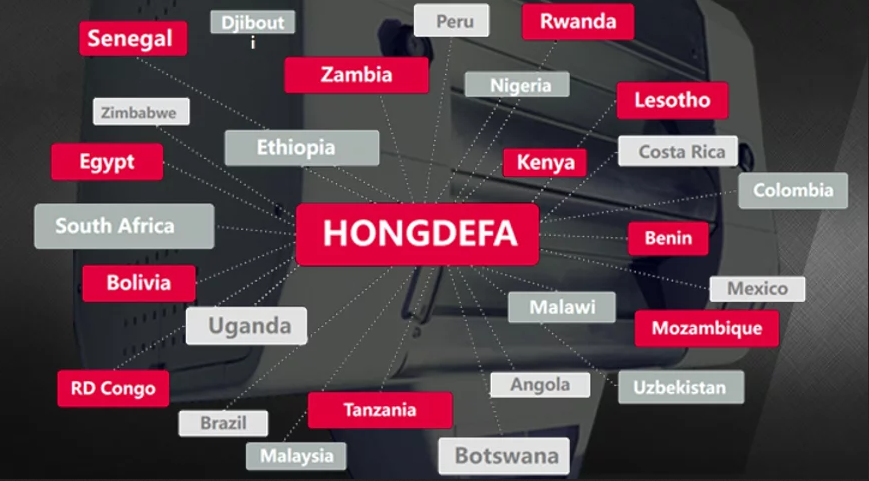

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of OEM manufacturer Modern Wheat Mill Plant - 500 T/ 24H MAIZE FLOUR MILL – Hongdefa, The product will supply to all over the world, such as: Wellington, Croatia, Jordan, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

-

Manufactur standard Wheat Bran Finisher - 120/...

-

High Quality for Wheat Flour Milling Machines -...

-

2017 China New Design Maize Flour Processing -...

-

OEM/ODM China Wheat Milling Machine - 50t/24h ...

-

Good User Reputation for Maize Mill Plant - 80...

-

Hot-selling Maize Processing Equipment - 80t/2...