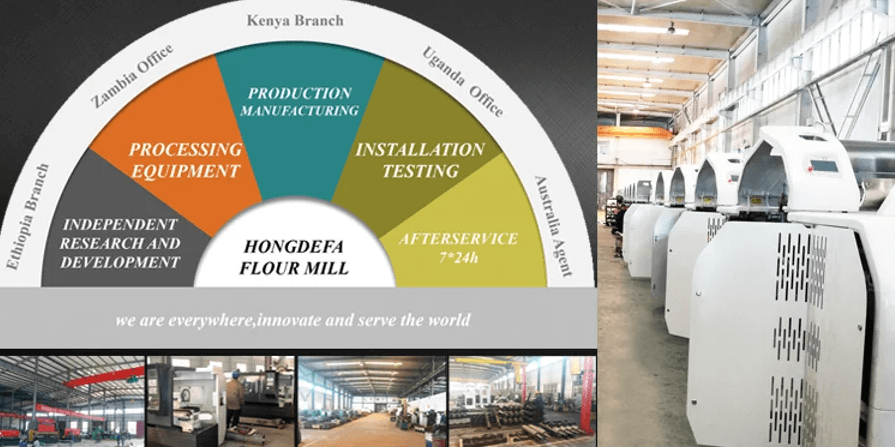

What’s the specifications of wheat mill plant?

1. Input wheat –wheat cleaner– wheat moisture dampener–roller mill–plansifter–good quality flour –packing

2.The control system: Control panel control or PLC control

3.Pipe in milling section is stainless steel

4.auto-roller mill and plansifter

5.European Condition dampener

1. Technical level:

- Capacity: Processing wheat 500T /24H.

- The equipment can produce best flour, great flour, special flour and standard flour. The quality of flour could compare with European product.

2. Cleaning Technology:

Cleaning system adopts 4 sieves, 2 beating,1 brush, 2 destoner, 2 Damper moisture, 3 magnetic selecting. This producing line adopts second moisture wheat technology. This increases the toughness of coat and assures the complete of bran.

3. Milling Technology:

Milling system adopts 4B,7M, 2S,2T, middle and rear line beat bran, four purifying flour. The characteristics of the technology are purifiers with wheat duster, assured more good quality wheat flow into the central mill. Assured flour rate and quality.

Workshop and wheat storage

The workshop is 6 floors of ferroconcrete structure.

The total length of workshop is 51.3m, 9.4 m width and 33m high.

The total acreage is about 461.7 square meters.

The raw wheat tank is 10 thousands capacity silo.

There are 8 moisture wheat tanks, a high level water tank on the top of workshop and a high level control water tank.

These provide water for producing and fire protect