Technology guarantee:

a)Guarantee for maize cleaning

The impurity content of the dust should not over 0.3%

The sand stone content should not over 0.02%

b) Waste

After sieving,in each kilogram of crushed stones, the plump corn is not over 100 grains.

After careful sieving, in the wasting things, the good corn is not over 0.01%

After careless sieving, in the wasting things, the good corn is not over 0.01%

In the tailings, the plump corn shouldn't over 0.01%

The form of the package:

Woven bag :50 kg/ bag ( bran, embryo and so on)

Weave bag:25 kg/ bag ( finished product)

Small package:10 kg/bag, 5 kg/bag, 2.5 kg/bag( finished product).

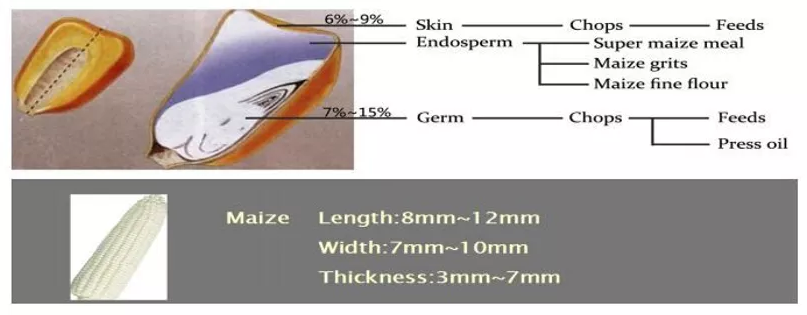

THE MILLING PROCESS

The process of manufacturing the products involves three fundamental sub-processes. The first of these, physically detaches the three components of the maize kernel from each other. with as little dilution or mixing as possible.second, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product

Required The aim of the process then, is to detach the bran and germ from the maize

kernels with a minimum disintegration of either the endosperm or the bran/germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of camp to the very Fine maize flour. Some of the bran and germ are also ground down in the process and a certain amount combined with the ground endosperm to meet the specifications of the coarser meals such as sifted and unsifted maize meal.